Coke Oven Machines

COMET TECHNOLOGIES manufactures a range of material mixing equipments. Manufacturing range includes,

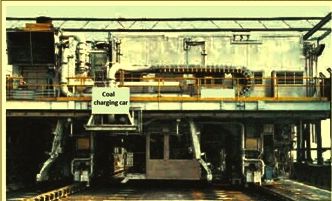

Coal Charging Car

- Coal charging car is used to charge coal blend into the coke oven.

- The coal charging car is designed for single spot operation and equipped with the technologies related to pollution control, and safe and efficient operations.

- COMET Designs, Manufacture, Supply Coal Charging Car as per your existing or recommended capacity. Also provides Erection, Testing, Trial Run, and Commissioning with commitment of Performance Guarantee.

- Electrical System, drive automation, handling facilities, Instrumentation, automation, intercommunication, interlocking, air-conditioning, ventilation, pollution control measures & illumination provided as per clients recommendation.

Coke Pusher Car

- The coke pusher machine travels along the length of the battery and carries out various functions such as (i) remove and replace coke oven doors, (ii) push out hot coke from the oven, (iii) open and close leveler bar doors, (iv) level the coal charge in the oven, (v) clean doors, frame and flash plates, (vi) de-graphitize the oven ceiling, and (vii) remove the coke spillage. The pusher machine is located at the coke oven battery side and is normally designed for the single spot operation.

- COMET Designs, Manufacture, Supply Coke Pusher Car as per your existing or recommended capacity. Also provides Erection, Testing, Trial Run, and Commissioning with commitment of Performance Guarantee.

- Electrical System, drive automation, handling facilities, Instrumentation, automation, intercommunication, interlocking, air-conditioning, ventilation, pollution control measures & illumination provided as per clients recommendation.

- Operator’s cabin and the hydraulic and electronic equipment cabins are equipped with air-conditioners.

Coke Quenching Car

- COMET Designs, Manufacture, Supply Coal Charging Car as per your existing or recommended capacity. Also provides Erection, Testing, Trial Run, and Commissioning with commitment of Performance Guarantee.

- Electrical System, drive automation, handling facilities, Instrumentation, automation, intercommunication, interlocking, air-conditioning, ventilation, pollution control measures & illumination provided as per clients recommendation.

- COMET’S Quenching Car operation includes waiting near the oven to be pushed, receiving the hot coke from the oven, transportation of hot coke to quenching tower, transport & discharge quenched coke on to the coke wharf, travel to the next oven in the battery to be pushed, positioning of the quenching car along the oven to be pushed.

Door Handling System

- COMET designs, manufactures and supply hydraulic or rope winch type coke oven door lifting arrangements.

- Also provides Erection, Testing, Trial Run, and Commissioning with commitment of Performance Guarantee.